alterBiota is a green materials company focused on cost effective concrete decarbonization.

Concrete is one of the most ubiquitous materials on earth but making it is extremely carbon-intensive. Through an innovative and highly scalable approach we make a natural admixture called hydrous Bio Graphene Oxide (DeltaC or ∆C) that enables concrete producers to use less cement while storing stable, biomass derived carbon for 1000 years in concrete infrastructure.

∆C is remarkably easy to use – just like other liquid admixtures – and improves other properties of fresh or hardened concrete.

Adding a dose of ∆C to a typical load of concrete enhances compressive strength allowing for reduction of levels of cement, the carbon intensive binder in concrete.

Unlike other concrete decarbonization technologies, ∆C is a scalable, drop in decarbonization solution that can be implemented without a hefty green premium, and concrete producers benefit from carbon credits associated with cement avoidance.

With alterBiota, concrete producers and their customers reduce their carbon footprints and we all benefit from more sustainable growth.

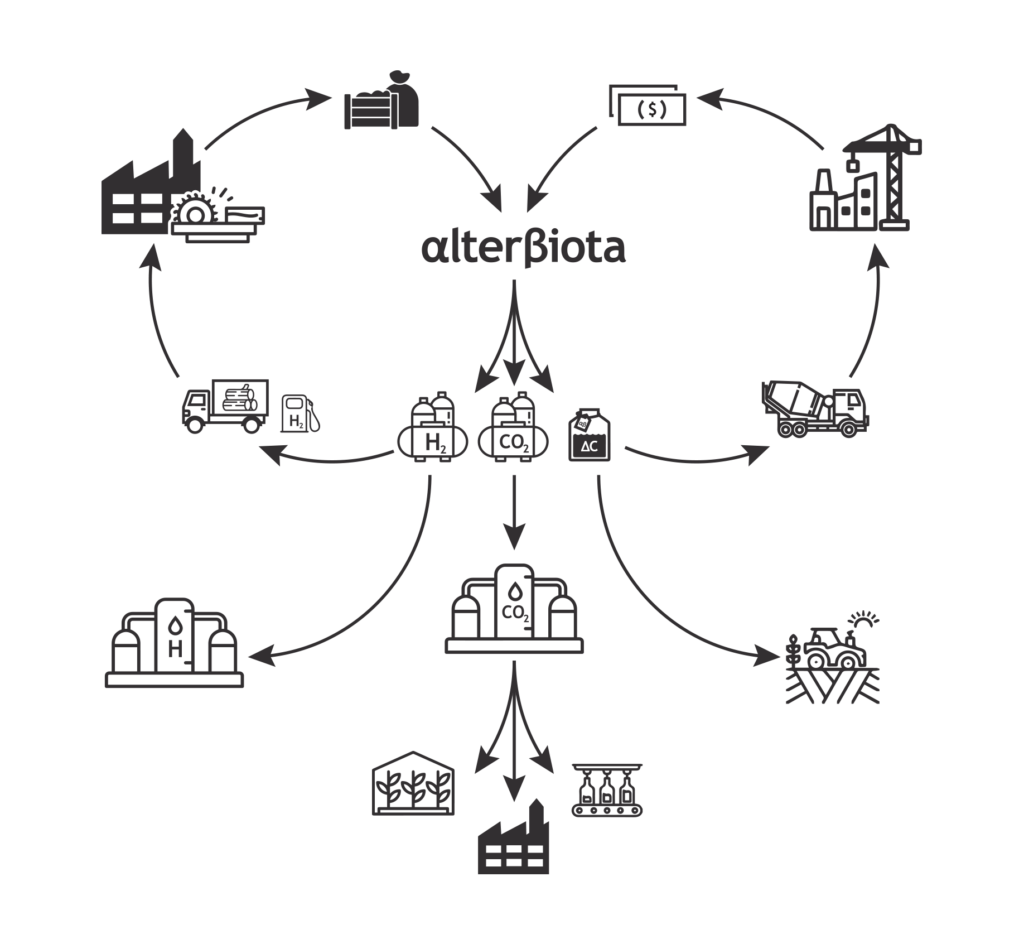

Our circular manufacturing process is sustainable, efficient, and revolutionary.

We diversify revenue by turning byproducts into climate solutions for some of the world’s most carbon-intensive industries.

Play the video to learn more.

Circular Manufacturing in Action

Atmospheric CO₂ by-products can be utilized in a number of industrial

applications like greenhouse, manufacturing and beverage canning.

Hydrogen by-products can flow back to fuel fleet vehicles in the milling process as well as other industries.

Our ∆C goes into the concrete industry to improve the flexural, compressive and sheer strength

of concrete to reduce the amount needed and saving costs while reducing carbon footprint.

Utilizing milling industry by-products turns waste into 100% usable outputs.

Hydrogen by-products can be liquified and stored offsite and supplied into other industries.

Additional opportunities for ∆C are in feedstock and agricultural applications.

We use a circular economy approach to our entire business because we believe in extracting maximum value out of the resources at our disposal. Using by products from the forestry industry and applying our own ingenuity, we create a proprietary product capable of drastically decarbonizing the construction industry with stronger, greener concrete. In addition, we’re careful to ensure the useful by products of our production are put to good use. Those include hydrogen that can be used as fuel and industrial CO₂ that can be used in greenhouses, beverage production, and concrete producers.

digitalΔggregate™

αlterβiota’s digitalΔggregate™ maximizes the quality and consistency of concrete mixes, drives cost savings and gives producers access to unprecedented data into their mix design. Using cutting-edge computer vision technology that captures inline, real-time images of aggregates during concrete batching, digitalΔggregate™ enhances the quality control process and sets a new standard for precision, efficiency, and reliability.

Address

80 Marine Dr

Edwardsville, NS

B2A 4S6

Contact Us

Proudly Supported By